Have you ever wondered what the best finish for pine is? If you’re like me, then you choose to work with pine wood for two obvious reasons – the cost and availability. Pine is also easy to work with, and durable enough for making shop storage and small furniture.

There’s no absolute best finish for pine wood. Every woodworker has their unique formula for finishing pine. Plus, there are many variations of pine, so each finish may look different on different species of pine.

There are tons of ways to finish pine; paint, polyurethane, shellac, and the method I love the most, using an oil-based finish. Oil-based finishes are easy to apply, adds some protection to the wood and give it a natural look that ages pretty well.

But there are so many different types of oil-based finishes, which one is the easiest and most natural finish for pine?

My Experiment To Find the Best Finish for Pine

I don’t have every single oil-based finish in the world. But I do have four of the most common – Hope’s tung oil, Klean Strip boiled linseed oil (BLO), Tried & True Danish oil and Howards cutting board oil.

I don’t consider Howards’ cutting board oil to be an actual finish for pine. It’s more of a “moisturizer” for wood that comes into contact with food, like cutting boards or bowls. So that leaves me with three different oil-finish for pine.

The experiment is simple. I wanted to test how each of these three finishes looks and feel like on pine over time. I wanted to see how each finish changes the colour of pine when I first apply it, and after a few weeks exposed to sunlight.

Danish Oil Vs. BLO Vs. Tung Oil

This is NOT a scientific experiment. I get that!

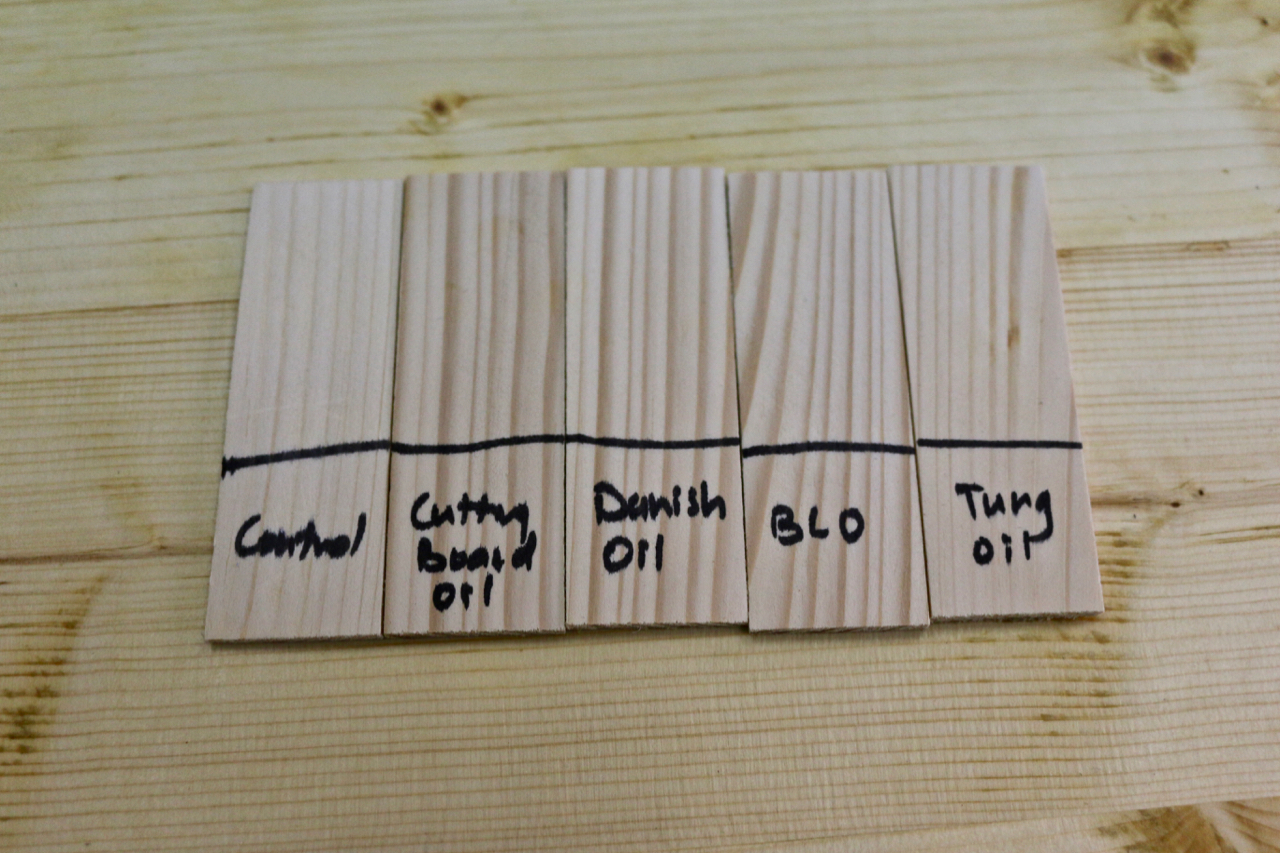

Think of it as an amateur experiment just for fun. I have five thin strips of pine cut from the same stock of Doughlas Fir pine. One will serve as a control, with absolutely no finish whatsoever. The other will be wiped with a moderate amount of cutting board oil. The remaining three will be treated with Danish Oil, BLO and Tung Oil respectively.

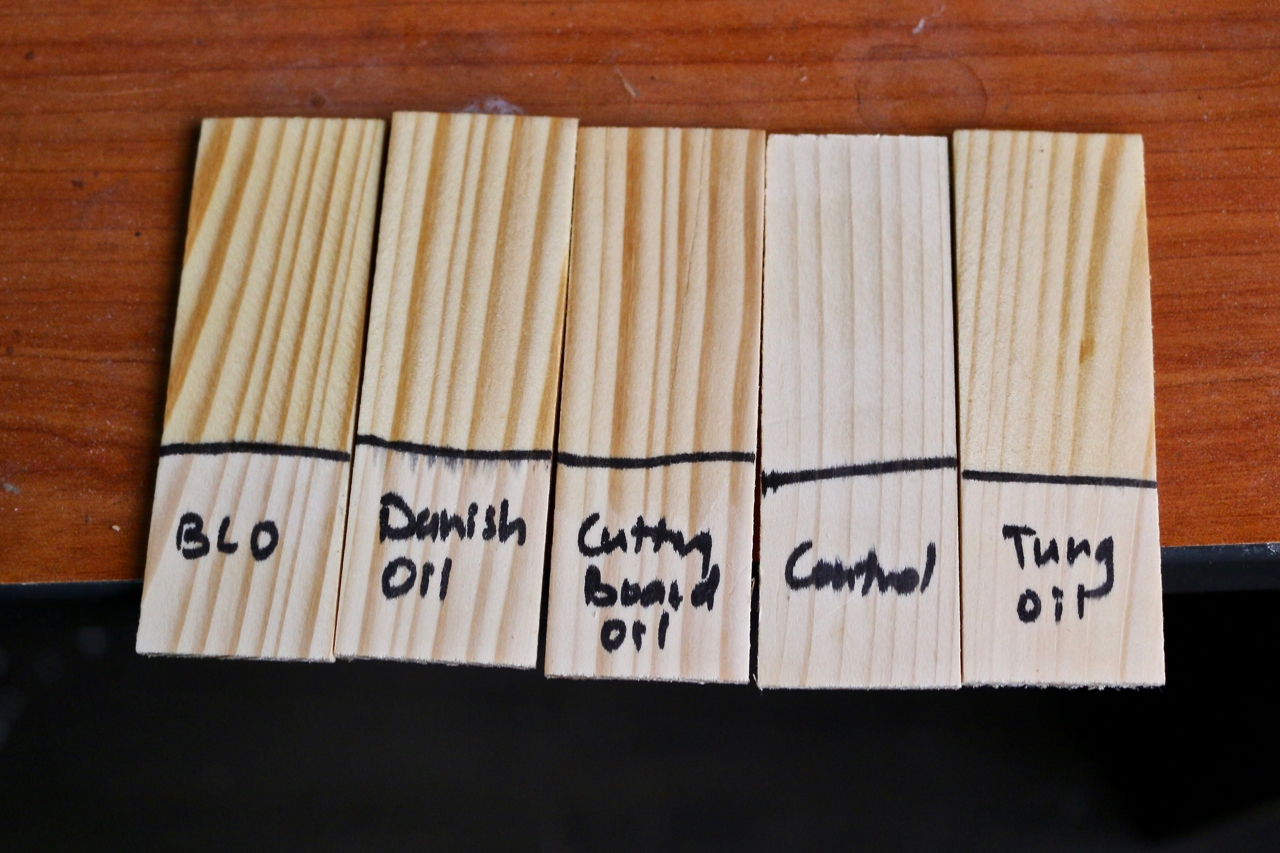

After about 20 minutes of applying them, I noticed that Howards’ Cutting Board oil was the runniest of them all, but Danish oil was pretty thin and runny too. Tung oil and BLO were thicker.

BLO seemed to darken pine the most, followed by Danish oil. The cutting board oil seemed to result in the same shade of colour as Danish Oil. However, I knew that cutting board oil does not cure and will evaporate away eventually.

I left the experiment exposed to direct sunlight in my workshop and observed the changes two months later.

As expected, the cutting board oil has evaporated away, but not as much as I thought it would. All the other oil finishes darkened a bit, but Danish oil darkened the most. The tone of Danish Oil was pretty close to BLO after two months.

How about the odour?

To be honest, I hate the odour or smell of BLO and Tung Oil. Danish Oil had a more pleasant smell, while Howards’s cutting board oil never had any kind of scent. Plus, due to the humidity of my workshop, BLO felt like it took ages to cure.

After two months, BLO still felt tackier than the other finishes for pine. It attracts more dust than all the different finishes. I could just be this particular brand of BLO, so I’m still willing to try other brands to see if there is a difference.

Going forward, I’m going to be using mainly Tried & True Danish oil. I used it on my DIY chisel box and chisel handles. I love how it looks not just on pine, but other woods as well.

From my experience, it is the overall best finish for pine, as far as oil-based finishes are concerned.

3 Responses

Thanks for the test. But Tried and True Danish oil is really pure polymerized-linseed-oil. That’s not really traditional danish oil. I know the is no exact formula for Danish oil and everybody’s Danish oil is different but it’s usually some kind of mix of finishes.

How do you preserve pine with the fresh cut natural color? I have seen this on Swedish furniture where the color does not change with age.

You could use a sealer, that will not change the fresh cut color.