Before you read this review of the Black & Decker Workmate 225 portable workbench, I have to warn you that I’m not a professional reviewer. However, what I buy for myself, I try to review the best I can. It might just benefit you.

Also, I have never personally owned a portable workbench like this before. That being said, I did a whole lot of research before even thinking of driving out to my favorite hardware store to get it.

In a nutshell, the Black & Decker Workmate 225:

- It is a portable workbench and sawhorse priced at about $70.

- Has vice jaws and plastic bench dogs for multiple clamping options.

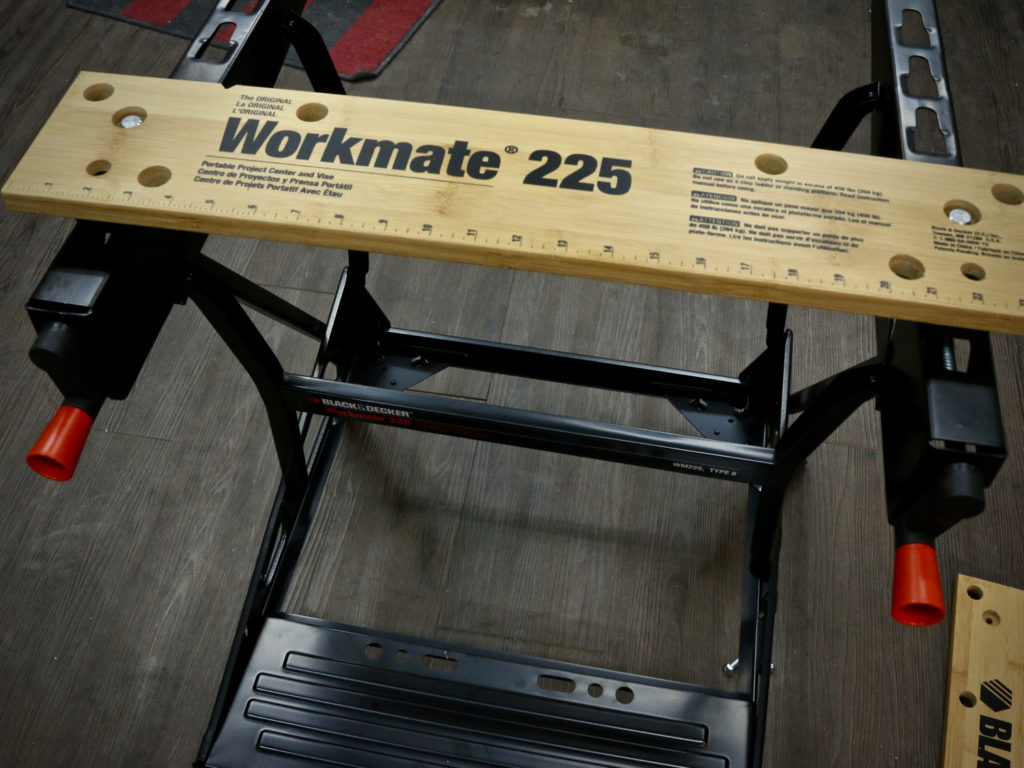

- The foldable body is made of steel and can support up to 450 pounds.

- Measures 30.2 x 6.8 x 24.1 inches and weighs 28 pounds.

So let me give you the breakdown of how I put this thing together and my first thoughts on it.

Assembling The Black & Decker Workmate 225

As you can see, the box is pretty much intact after I opened it. I’m not usually this gentle, but I guess it was god’s way of helping me out.

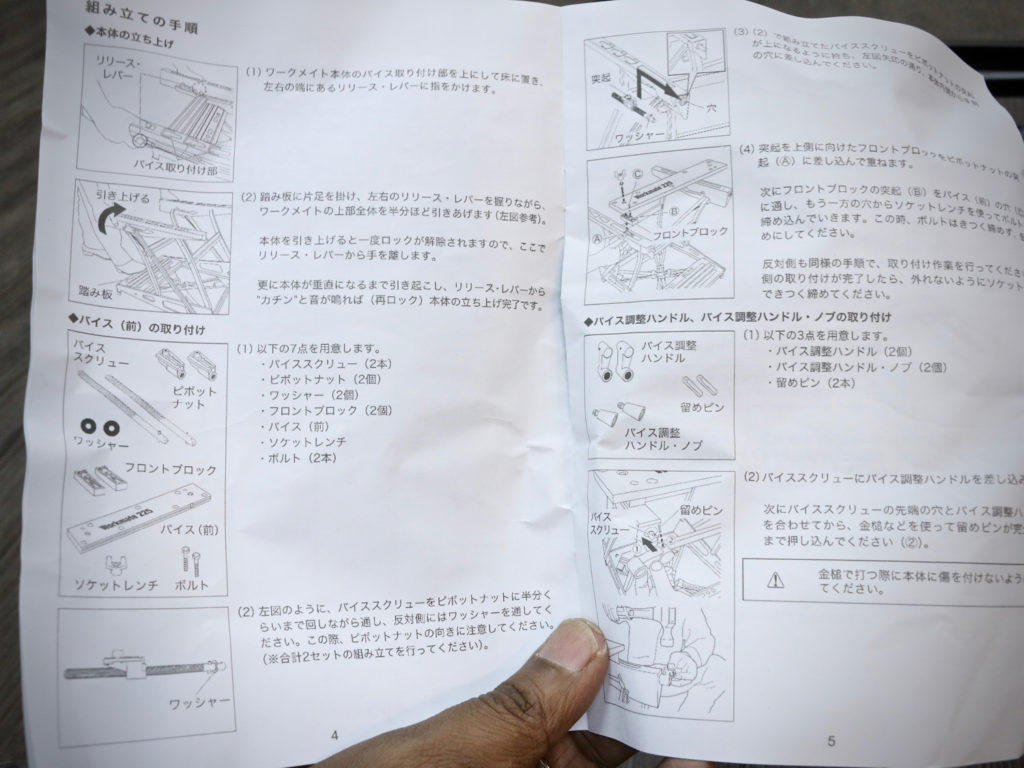

As I quickly found out, the manual was in Japanese. So the box was all I had to fill in the gaps. The illustrations only explained about half of the steps required.

The main workbench frame and legs were all pre-assembled.

Two levers and springs lock and release the steel frame. These were clean and not worked perfectly.

Here’s everything else from the box, including two wood panels with holes in them for the bench dogs.

The vice mechanism assembly was the most important part. Since I could not understand Japanese, I had to use common sense a bit of trial and error to get both lead screws in the correct position. A plastic injection-molded piece held up each screw in position.

The provided bolts and plastic bolt driver both worked perfectly, although I didn’t know what it was for a while. The lever assembly was straightforward, and the illustrations were good enough.

The front panel and vice assembly is the only half that is fixed. The other half can be placed in any of the three available slots, allowing you to adjust your work-holding area quickly relative to the vice.

Finally, I completed the assembly and was ready to test out the Black & Decker Workmate 224 portable workbench.

My 1×4 walnut lumber clamped firmly, although I had to use the base of the vice to clamp it. I was able to saw comfortably by putting my left hand and leg on the bench itself for weight.

It clamped down on round stock pretty good too.

The bench dogs worked great and held my workpiece quite securely, for both horizontally and vertical clamping.

However, it’s when I tried planing that I first had issues. The Black & Decker Workmate 225 just doesn’t have enough weight for planing operations. I tried putting half my body weight on the bench, which worked for thin shavings but resulted in some awkward planing angles.

For thicker shavings which required more force, I needed to stand both feet on the bench’s step to apply enough weight so that the bench itself doesn’t move. In other words, it’s a pain to plane wood on the Workmate 225. I believe this should be the same story for similar portable workbenches.

Folded, it takes up very little space in my humble workshop. I can install some hooks to get it mounted if I want to in the future.

My Thoughts on The B&D Workmate 225

Before getting the Workmate 225, I was clamping stuff on my desk (old office table) using any clamp I could find. It worked just perfectly for sawing and screwing, but when I started using the hand plane a lot I realized that I needed better work-holding options.

I was planning to build my custom workbench from 2×4 pine wood, but wanted to do a lot of research and drawing up designs first. I also had to shop for a sturdy and high-quality vice mechanism and figure out how the correct dimensions for it so that I could also use it as an out-feed table for my Bosch GTS10-J table saw.

It seemed like a lot of moving parts, and I just wanted something simpler until all these parts started coming together. This is the main reason I got the Workmate 225.

It turned out to be quite a good sawhorse and a good overall bench for clamping and screwing together pieces of wood for my small projects. If you’re planning to do a lot of outdoor projects, then you want to pick one up from Amazon here. At under $70, I think the price is good for the quality and construction.

But the one thing that I wanted it to do – hold lumber securely to be planed – I couldn’t get it to do.

Perhaps, I could try backing the entire workbench up against the wall so it would not move when I planed on it. I’m sure someone smarter has figured out a way, I just can’t seem to find anyone who has shared anything about it online.

Perhaps now I can focus on just getting my first real workbench built. Something heavy, sturdy, and mean.

5 Responses

Just bought one at Best Buy and very disappointed. The instructions were bizarre in their sequence and confusing (no words, unclear pictures). It feels cheap. One of the orange plastic dogs has already broken, and one of the pins that connects the vise handle is absolutely too big (or the opening is too small) to go through fully.

Yes it was pretty confusing, and I got it wrong the first time. I think they do this so that they can sell it everywhere without having to worry about language.