I’ve watched a lot of videos about making spline-cutting jigs, but I’ve never seen one about building a spline jig for the actual wood spline.

When I started making more wooden jewelry boxes and wood watch boxes, having splines the perfect size became really important for making solid spline joints.

Previously, I was cutting them on the table saw and sanding them for fit. This was extremely slow and resulted in wood splines that were either too tight or too loose.

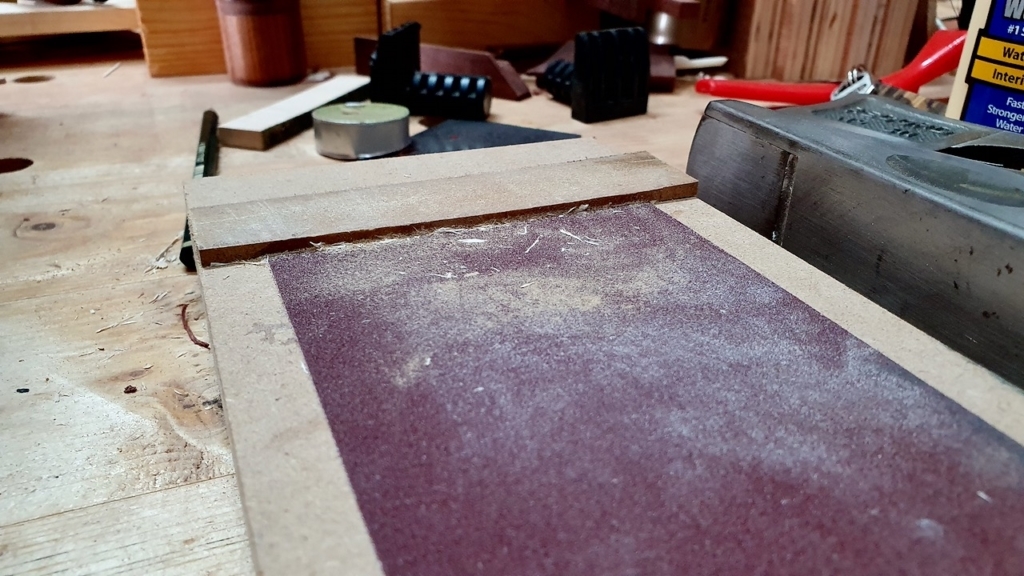

Today, I tried making a really simple spline jig from a single sheet of 1″ MDF (Medium Density Fiberboard). To my surprise, it was really easy to do and took me no longer than 15 minutes.

As you can see, it’s really simple. There’s a thin sheet of MDF that acts as a stop block, measuring the same thickness as my table saw blade, which is 3mm or 1/8″.

I stuck some 150 grit sandpaper which acts to hold the splines in place while I plane them, but also as a tool to remove very tiny amounts of wood for a perfect fit.

I cut a rabbet and glued in a smaller piece of MDF that I cut from the same block. This allows me to hold the spline making jig in my 10″ Yost bench vise.

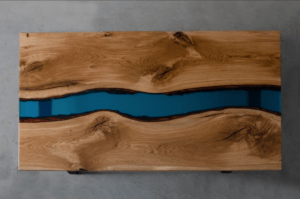

Making Wood Splines for My Spline Joints

I cut some stock and plane it down to slightly larger than 3mm (1/8″) using my Taytools Jack Plane. Then I cut off small rectangular pieces that are slightly longer than the length of my mitre joint splines.

I butt the small pieces against the stop and use my block plane to slowly take off a little bit at a time, and test-fit the splines as I go. The whole goes very quick even for these Maple hardwood splines.

I tried using a #4 smoothing plane, but I find that I get better control with the Stanley block plane. Make sure your plane has been sharpened properly, of you will find it hard to take cuts from these tiny strips of wood.

When I need to take off less than a single shaving, I use the sandpaper. Over time, the stop block is going to wear off, and I can easily plane it down and replace it.

In future, I might make the stop completely replaceable so I can easily make thicker wood splines by using the correct width stop block.

So far, this spline jig has been working great. Such a simple design that anyone can make, but good enough for most spline joints.

In fact, you can use this jig for making any thin piece of wood, for any purpose. My jig is just the right size for my needs, but you can easily scale this up if you work with larger projects.