The Ultimate DIY Workbench Building & Customization Guide

Everything You Need to Know About Designing, Making and Improving Your DIY Woodworking Bench on a Budget!

Whether you’re a hand-tool or power-tool woodworker, building your first DIY workbench is crucial. Although you can save a lot of time by getting a pre-made woodworking workbench, building one allows you to customize the size, shape, and functions to match your needs.

I’ve built two DIY workbenches myself. The first was tedious, and I used primarily hand tools. The worst part was building a workbench without having a workbench to help you mill lumber and create joinery. Somehow I managed, and this now beat-up workbench is still my primary work table.

The other is a smaller, mini-classical workbench with better planning and execution. This workbench used to sit on my condo balcony and has helped me get through the boredom of multiple COVID lockdowns. It is not my second workbench in my new woodworking workshop.

The good news is that you can quickly build a workbench and equip it with affordable vises and jigs to help you reach the next level in woodworking. Here are a few considerations:

- What is your budget? Determining a budget before you start is essential, or the costs can get out of control. You can build a cheap pine workbench or use expensive hardwoods. Calculate the cost and all the clamps, fixtures, and jigs you want to add to your workbench.

- How much time do you have? A DIY workbench can be built in a few hours, or it could take months. Don’t fall into the trap of thinking a workbench should last forever. Some workbenches can be built quickly, then improved, or recycled for future projects.

- How big is your space? In the US, most people work from a single-car garage. This should be enough space for a woodworking hobby. Build according to your space.

- Hand tools or power tools? The design will vary according to the tools the workbench will support. Sometimes, you may want the best of both worlds, and that’s okay. However, there should be a primary focus, or you’ll make a do-it-all workbench that doesn’t really do either job well.

I’ve listed everything you need on this page to research, plan, build, and equip your DIY workbench to become your dream workspace.

Hand Tool Vs Machine Tool Woodworking Workbench

Hand Tool Workbench

The most important features of a hand-tools DIY workbench:

- Solid wood top – This type of workbench needs to absorb the impact of hammers and chisel work. Soft or hardwoods can be used.

- Weight & mass – Heavy and built with sturdy joinery to prevent racking and movement when planing wood.

- Workholding options – Vises, clamps, bench dogs and fixtures help you work better with hand planes and saws.

Roubo & Nicholson workbenches are the dream of all hand-tool woodworkers. However, there are other styles of DIY workbenches that cater to hand tools, and are simpler to build.

Here are a few hand-tools DIY workbench examples to get you inspired. You can also see our list of best budget & premium workbenches to get an idea of commercially-made hand-tool workbenches.

Here are some examples:

Power Tool Workbench

Powertool users have different needs. Their workbenches (or workstations) tend to reflect that but with some minor elements from a hand-tool workbench.

The most important aspects:

- Large surface area – These workbenches tend to house one primary power tool such as a table saw or miter saw. The bench height and size tends to complement the tool

- Plywood & screws – They tend to make use of plywood for the tops, and pocket-hole screw construction for reasonable solid but extremely future-proof joints.

- Mobility and storage – A lot of these DIY workbench with storage have casters or rollers, because they are typically stored indoors but moved outdoors

- Power & dust collection – Design for power outlets and dust collection, as power tools produce lots of high-velocity dust.

Here are a few DIY workbench examples for power tool users.

DIY Workbench Tools & Accessories

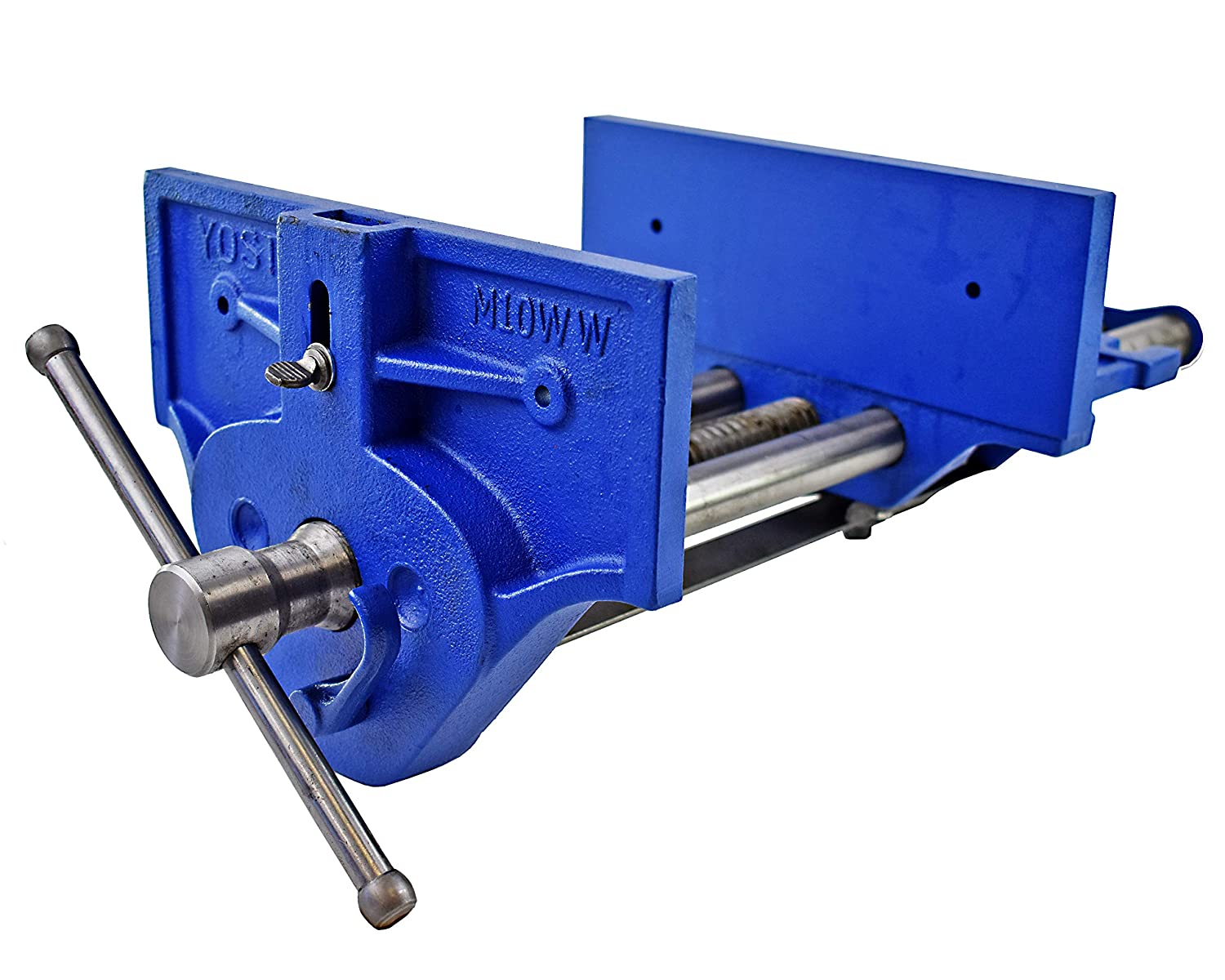

Whether you’re building a hand-tool or machine-tool workbench, having a vise will definitely come in handy. Yoast makes many great vises, but this version has a stainless steel handle, quick release, and built-in bench dog.

All you need to do is attach it to your homemade workbench and use your choice of hardwood as the vise face. I’m using a Yost 10″ vise with a turned wooden handle in my primary workbench, with a smaller Irwin vise on my mini workbench.

Alternatives:

Workbenches can get pretty heavy and difficult to move. The simple solution is to add a Powertec workbench caster.

This foot-activated “stepdown” caster can carry huge loads, up to 400lb (180kg), and can be fitted to any type of workbench. You get a drilling template that allows you to accurately drill the required mounting holes.

I have a full review of the workbench caster, and I’ve been using it happily for months. It made my unmoveable workbench mobile almost instantly.

Alternatives:

Bench dogs are very useful for planing and clamping your workpiece. The clips on each dog allows you to push it inside the hole to the required height, and even push it all the way in and flush with the top.

This puts it out of the way, and you can just put it back up from the bottom when you want to use it. Made from aluminum and sold in packs of two.

Alternatives:

Holdfasts are great for quickly holding down a workpiece while you saw or chisel. They fit into 3/4″ dog holes drilled in your workbench. Tap them in with a wooden mallet.

Make sure that you have enough clearance underneath the workbench top in order to use these.

You can also use them if you have dog holes drilled into the sides or the legs of your workbench to secure stock vertically.

Alternatives:

These bench cookies have non-slip pads on both sides. Use them to hold your workpiece while sanding or finishing.

Since it lifts your workpiece off the surface, it’s also great for cutting with jigsaws and circular saws.

You can buy add-on cones that attach to the cookie, for minimal contact when painting your workpiece.

Alternatives:

Hand-Tools Workbench "How to Build" Videos

This is workbench how to build video I made for my easy DIY workbench with drawers, taking inspiration from some Sjobergs European-style workbenches. No dovetail joints or anything complex. You can scale up this design for larger workbenches. I also built a storage cabinet for it.

Complete Roubo workbench with leg vise and tail vise, made from Southern Yellow Pine. Making this hand tool workbench takes a considerable amount of skill and a lot of tools.

Power Tools Workbench "How to Build" Videos

This video shows you how to use pocket hole joinery and 2×4 construction lumber to create a basic DIY mobile workbench. The top is made from plywood. Heavy duty casters give it complete mobility.

This is a super quick and dirty workbench build using 2×4 lumber, plywood and a thousand screws. No fancy joinery, no pocket holes, just basic techniques.Heavy duty casters for mobility.