Narex chisels are very popular among woodworkers since a good Narex chisel set will probably last them a lifetime. If you’re ok with making your handles, you can own a set of six chisels – 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, and 1″ – at a great price. In fact, the Narex unhandled chisels you see in this review cost me only $42.

You can also pick up individual Narex unhandled chisels in different sizes for just $11, if you just want to add a size to your existing set of chisels.

As far as I can tell, these are indeed made by Narex in the Czech Republic, but without the Narex logo. The blades are fine-grained chrome-manganese steel hardened to a Rockwell hardness of 59.

The higher-end Narex Richter chisels are hardened to a Rockwell hardness of 62HRC. So these are not the toughest chisels Narex makes, but they are the standard Narex HRc, as far as I can tell.

The factory grind on this Narex chisel set is at a 25-degree angle. The factory grind is good enough for cutting hardwood and does a decent job with pine.

However, you must still lap the back and resharpen the blades to get a “scary sharp” edge. It will also be easy for you to add a 30-degree micro-bevel, which I did quickly.

They are of excellent quality, with good straight bevel edges. Unlike the edges on my Stanley Sweetheart, these do not taper.

Making Handles for The Narex Unhandled Chisels

As I said, these are unhandled Narex chisels, so you must make your handles. There are many ways to make chisel handles, but it’s much easier if you own a wood lathe and good lathe tools.

Here’s the video I recorded showing you how to make your own chisel handles.

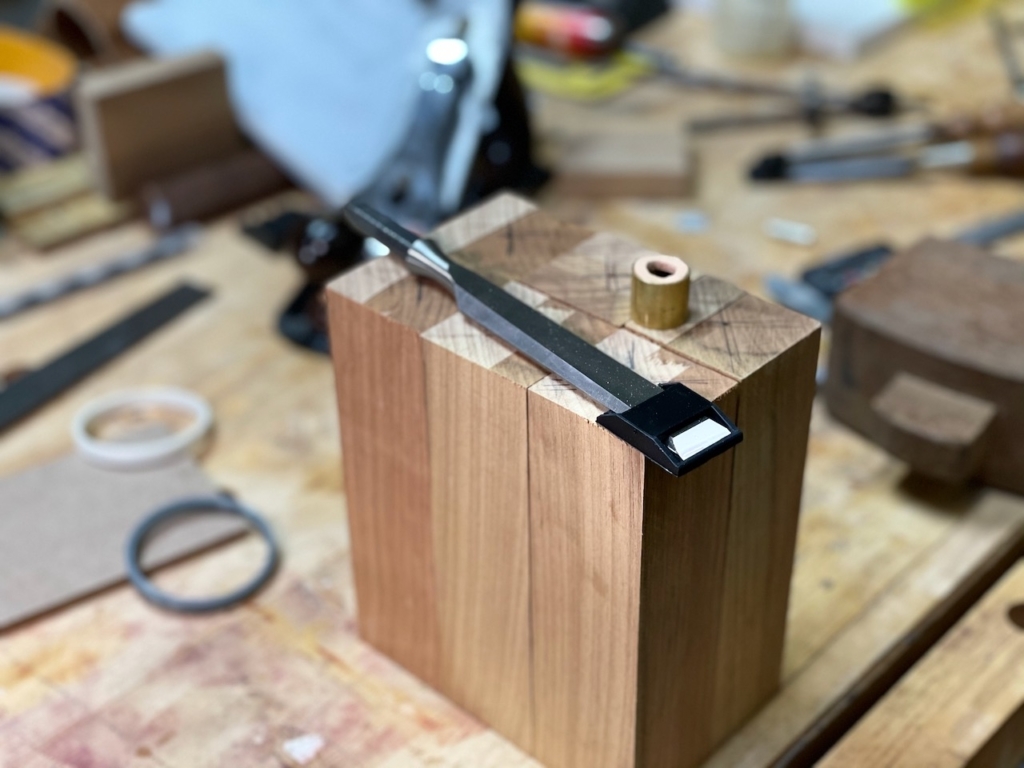

These come with solid brass ferrules and leather shock absorbers. You can also make your own ferrules from brass or copper pipes if you want something smaller.

I found that creating a handle template makes all the difference if you want your handles to be as uniform as possible.

Also, drill a 3/8″ pilot hole on a piece of scrap to test fit the tangs of these Narex chisels. The right size hole is critical, and you want to ensure a good fit before making your handles.

I found a block of quartersawn Iroko that was just the perfect length to make six handles. I used CA glue to finish my Narex chisel handles as they cure instantly. Then, I polished them with Minwax Finishing Paste Wax.

Although there are some inconsistencies between the handles, these turned out much more uniform than my previous chisel handles. This is because of the template I created by studying my favorite designs.

Hammering in the blades was the easiest part, and they fit perfectly. I loved the finished chisel’s balance and weight.

I am thrilled with this Narex chisels set. These perform just as well as my Stanley Sweetheart set, which costs much more for an 8-piece set. If you’re comfortable making your handles, get yourself a set of Narex unhandled chisels. You won’t regret it.