What are the benefits of buying rough-sawn lumber vs. S4S or S2S lumber? When I first started buying pine wood from a local supplier, I never knew I could purchase rough-sawn pine. I also perhaps never understood what “rough sawn” really meant.

The word “rough” is probably enough to convince new woodworkers to stay away. When I first saw what rough-sawn lumber looked like, I wondered why on earth would someone want to buy it in that condition.

So let me shed some light, based on what I have learned and researched, are the differences between rough-sawn lumber and processed lumber.

What is Rough-Sawn Lumber?

When a tree is processed at a lumber mill, the first stage of cutting the lumber up into dimensional lumber is known as the “rough sawn” stage.

Usually, a huge industrial bandsaw is used to cut the tree into standard dimensions such as 1×4 or 2×4 inch boards. At this stage, a 1×4 board measures exactly (or very close to) 1 inch thick by 4 inches wide.

Rough-sawn lumber can be cut from kiln-dried stable wood or “green” from a tree that has just been felled. It depends on the size.

If it is cut from green lumber, it will warp, cup, and twist during the drying process. Sometimes, the edges of rough-sawn lumber crack while drying. The wood is rough to the touch, and you’ll see tool marks from the bandsaw.

Rough sawn lumber requires a lot of work, either with a hand plane or a jointer and thickness planer. With the correct technique, you can get rough-sawn lumber square and smooth on all sides.

Here’s how a rough-sawn 2×4 pine board looks like after some (a lot actually) back-breaking work with my Stanley No.7 jointer plane:

To buy rough-sawn lumber, you’ll probably need to go to the nearest sawmill. You should be able to purchase rough-sawn lumber in all the standard dimensions, or the mill will cut according to your required dimensions.

Rough-sawn lumber is always cheaper than processed lumber, which is the main reason most woodworkers want to buy it.

What is S4S / S2S Lumber?

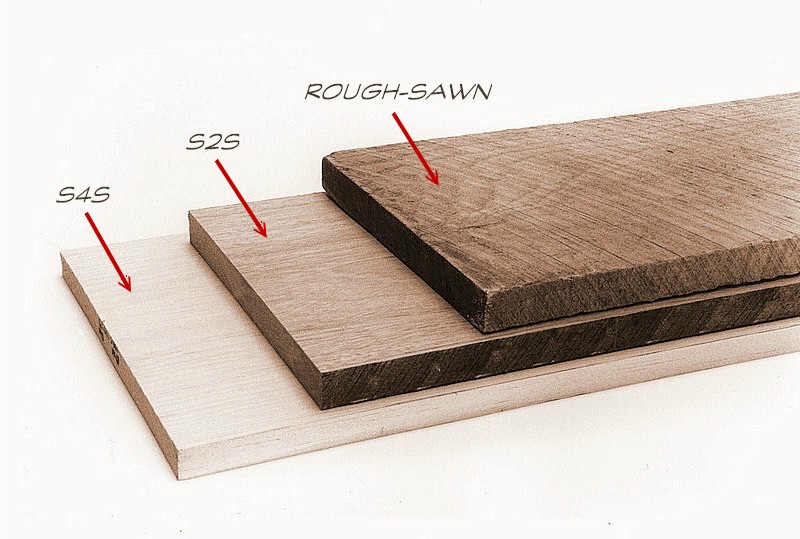

When lumber is processed, it is put through a jointer and planer. The jointer creates one flat edge and one flat face that is perpendicular to each other. These prepared surfaces are smooth and have less visible tool marks.

At this stage, it is called S2S lumber – which stands for “surfaced two sides.” (Some people refer to is as “smooth four sides” instead, although I believe the former is the correct one.)

These two sides are enough for a woodworker to work with. They can easily rip both sides with a table saw and get perfectly squared sides.

Further down the processing mill, the S2S is jointed and put through a surface planer. It is now perfectly square and smooth on all four sides, thus the name “S4S” or “surfaced four sides.” (From The Wood Whisperer)

As far as dimensioned lumber is concerned, this is the final product, which will be shipped to your nearest Home Depot.

Here’s how rough-sawn vs. S4S vs. S2S lumber looks like (photo credits).

A lot of woodworkers prefer to buy S4S lumber as it requires much less work. However, S4S lumber is smaller than what the nominal size suggests. For example, 1inch thick board ends of 3/4inch thick after it has been surfaced on all four sides.

To get a better idea of the reduction in actual size, refer to this nominal lumber dimension chart. As you can see, a lot is lost in the process, mainly because the lumber mill takes off more than it has to, to make all S4S boards uniform in size.

If you process rough-sawn lumber by yourself, you will lose less and end up with larger boards.

Rough-Sawn vs. S4S – Which One Is For You?

Ultimately, it comes down to money, time, and availability.

- What’s available? It’s easier to get rough-sawn pine than it is to get rough-sawn exotic wood. If you do not have access to a lumber mill, S4S lumber is usually what you can find. If you only need a short 1×2 inch board, it’s just much easier to find one that has been surfaced.

- Does size matter? If you’re looking for a particular thickness, it’s better to buy rough-sawn lumber and re-saw it yourself. If you do not have the tools to re-saw wood, buy rough-sawn lumber closest to your required thickness and plane the excess away with a hand plane.

- Do you want to save money? It is cheaper to get rough-sawn lumber. However, more work is involved, which also means you’ll spend more time processing rough-sawn lumber. Time equals money, so things even out. It might be worthwhile to pay a little bit extra.

- Do you want to save time? Getting processed S4S lumber means you have boards that are ready to cut and be transformed into furniture. However, if the S4S lumber has not thoroughly dried, you’ll still find cups and twists. Removing these will result in an even thinner board.

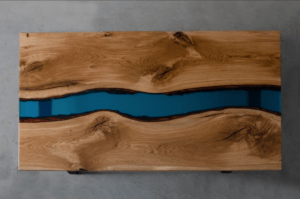

- Hobby or work? If you’re buying wood for a weekend project or learning a woodworking skill (like using hand planes), rough-sawn lumber is perfect. If you need to make something on a deadline to be sold, you’ll appreciate S4S wood. I built my walnut and maple coffee table with rough-sawn lumber, to learn how to flatten hardwood by hand.

To build my first workbench, I decided to buy rough-sawn lumber and save some money. I also wanted to make sure I get a tabletop that is as thick as possible from 2×4 pine boards. Besides that, I wanted to test out the new Stanley planes I bought from eBay and learn how to flatten boards by hand.

Did I regret buying rough-sawn lumber?

Yes and no. I loved the process of learning how to use hand planes. I loved learning how to sharpen the iron and restore old planes.

I loved the excitement of getting a smooth, square board without having to invest in a jointer and planer. I loved the moment I put two boards together and see the light between them disappear.

But after flattening about four pieces of 2×4 pine boards, I realized it was going to take me forever to get my DIY workbench completed. Then it became a chore instead of an adventure.

I became impatient and wished I had the lumber mill process the rough wood instead.

If you decide to buy rough-sawn lumber, refer to this guide on what to look out for. You’ll need to invest in a good jointer and benchtop planer, or a set of hand planes that include a No.7 jointer plane.

If you decide to buy S4S lumber, take note of the differences between nominal and actual dimensions. Make sure to buy wood where the actual dimension is larger than what you require since you might need to joint and plane it anyways.