Today, I decided to replace the cheap plastic on some of my smaller rasps with custom wood rasp handles. The whole project is very similar to the wood chisel handles I made, except that I will be making these from the cheap wood dowels I purchased recently.

I started with a 1-inch dowel. However, it was just slightly over an inch, barely fitting the jaws of my Nova chuck.

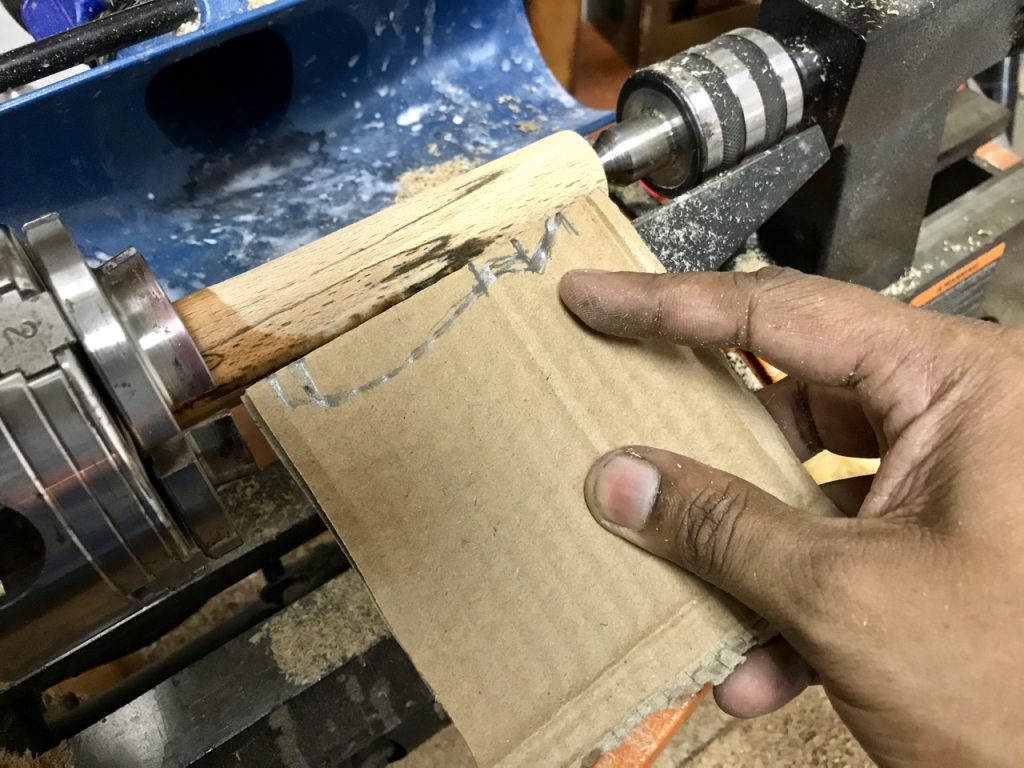

So I marked the center, turned a tenon between centers, then fit it securely into my chuck. There was some nice spalting on this $0.50 dowel, so I decided to use that part of the wood.

Based on a simple drawing, I marked the important points of the handle I wanted to shape. I then made a smaller tenon to fit the brass ferrules I made from brass pipe.

Drilling & Finishing The Wood Rasp Handles

I used medium CA glue and activator to attach the brass ferrule. Some people prefer to attach the brass at the final stage, but I feel like doing this earlier helps to reinforce the tenon for drilling.

Drilling the right sized hole is one of the most important things when making a rasp handle. I used two different bits to make a tapered hole.

Measure and drill by stages until you get a nice fit. The rasp tang should be able to fit halfway through the hole of the rasp handle. Check the full depth of the hole to make sure it will fit completely when you hammer it in.

I sanded everything to 600 grit and then with fine steel wool. A few coats of CA glue sanded with more steel wool produced a smooth, satin rasp handle. Then I parted off the handle, hammered in the rasp, and removed the stump with a chisel and sandpaper.

I’m quite happy with the way the wooden rasp handles turned out. By using the cheap wood dowels I bought from AliExpress, these two handles cost me $1 in materials!